Sonke siyazi ukuthi ekukhiqizeni amaphrofayili e-aluminium, inzuzo = ukuthengisa kususe izindleko zokukhiqiza.Ingqikithi yezindleko zephrofayili ye-aluminium ihlukaniswe ngezindleko ezingaguquki kanye nezindleko eziguquguqukayo.Izindleko ezingaguquki ezifana nerenti yezitshalo, ukwehla kwenani lemishini, njll.Ilungisiwe.Futhi izindleko eziguquguqukayo zinokuguquguquka okuningi.

Endabeni yentengo yokuthengisa yephrofayili ye-aluminium efanayo, izindleko zephrofayili ye-aluminium ziphakeme, inzuzo yehla iyancipha.Okwamanje, ngaphansi kwesimo esinzima sokukhuphuka kwamanani ezinto zokusetshenziswa, ukukhuphuka kwamaholo abasebenzi, ukwazisa kwe-RMB, ukukhuphuka kwamanani kagesi, ukwandisa umthwalo wentela nokunye, ukuncintisana embonini efanayo sekungene "okumhlophe-okushisayo" namuhla.Sesifikile isikhathi sokulawulwa kwezindleko ezinhle.

Ukulawulwa kwezindleko kuyisihluthulelo esiphethwe yibhizinisi kanye nomnyombo.Kuphela ngokuthola njalo isixhumanisi esibuthakathaka, amandla angaphakathi ezimayini, angasebenzisa zonke izindlela nendlela yokunciphisa izindleko, ukubamba iqhaza ngokugcwele, ukuqala emininingwaneni, kusukela ekunciphiseni imfucuza, i-aluminium. inhlawulo yokuqaliswa kokulawulwa kwezindleko, inganweba ngempumelelo indawo yokuphila kwebhizinisi, ithuthukise isimo sokuphathwa kwebhizinisi, yenze ibhizinisi ithuthuke ngendlela eqhubekayo, futhi isesimweni esingenakunqotshwa.

Ukulawulwa kwezindleko zephrofayili ye-aluminium kusekelwe ochungechungeni lwenani njengomhlahlandlela, ukulawulwa kwezindleko kuhlukaniswe ngezindleko zokuklama, izindleko zokuthenga, izindleko zokukhiqiza, izindleko zokuthengisa kanye nezindleko zesevisi.Ngoba ukulawulwa kwezindleko kuhilela indawo ebanzi, okuqukethwe kuningi.Ngizokhuluma mayelana nendlela yokuthuthukisa izinga lemikhiqizo eqediwe ngokombono wokukhiqiza ukuze kwehliswe izindleko zokukhiqiza.

Ngokuhlaziywa kwedatha nokusebenza, kufakazelwe ukuthi ukwenza ngcono isivuno samaphrofayili e-aluminium alloy kungenye yezindlela eziqondile nezisebenzayo zokunciphisa izindleko zokukhiqiza.Uma sithatha indawo yokusebenzela ye-extrusion njengesibonelo, izindleko zokukhiqiza izinto ze-aluminium zizoncishiswa ngama-yuan angama-25-30 ngethani uma isivuno sikhuphuka ngephesenti elilodwa, futhi ingxenye encishisiwe iyinzuzo yenetha yebhizinisi.Ukuthuthukisa i-extrusion. isivuno, umsebenzi wokukhiqiza ukunciphisa imfucuza extrusion.

Indlela yokuthuthukisa isivuno samaphrofayili e-aluminium ukuze kuncishiswe imfucuza ye-aluminium, kuthuthukiswe ukukhiqiza, nokunciphisa izindleko zokukhiqiza amaphrofayili e-aluminium, sifingqa imfucuza ekhishwe:

Imfucumfucu yamaphrofayili e-aluminium extruded ingahlukaniswa ngezigaba ezimbili: imfucuza yejometri kanye nemfucumfucu yezobuchwepheshe.Imfucumfucu yeJiyomethri ingumkhiqizo ongenakugwemeka wamaphrofayili we-aluminium alloy ngesikhathi sokukhishwa.Njengokuphuma kwezinto ezisele, imikhiqizo yokwelula kuzo zombili iziphetho ze-chuck, usayizi wezinto azikho ubude obanele bobude bezinto ezishiyiwe, usike isampula esidingekayo, i-shunt ehlanganisiwe iyafa egumbini le-shunt le-aluminium block esele, ama-ingots kanye nemikhiqizo ukusika usayizi wento ye-saw-blade. ukusetshenziswa kwama-chips e-aluminium nama-ingots e-aluminium adliwe ngesikhathi sokuhlolwa kwesikhunta.

Imfucuza yezobuchwepheshe imfucuza ekhiqizwa ubuchwepheshe obungenangqondo, izinkinga zemishini kanye nokusebenza okungalungile kwabasebenzi ekukhiqizeni iphrofayili ye-aluminium alloy.Ehlukile kumikhiqizo ye-geometrical waste, inganqoba ngokuphumelelayo futhi iqede ukukhiqizwa kwemikhiqizo yemfucuza yezobuchwepheshe ngokusebenzisa ukuthuthukiswa kobuchwepheshe nokuphathwa okuqinisiwe. .Imfucuza yobuchwepheshe ingahlukaniswa:

Imikhiqizo yemfucuza yezicubu: ukushisa ngokweqile, indandatho yokusanhlamvu eqinile, okusanhlamvu okuqinile, ukushwabana komsila, ukufakwa kwe-slag, njll.

Izakhiwo zemishini imfucuza engafanelekile: amandla, ubulukhuni buphansi kakhulu, akuhlangabezani nezindinganiso zikazwelonke;noma ipulasitiki iphansi kakhulu, ukuthambisa akwanele akuhlangabezani nezidingo zobuchwepheshe.

Imikhiqizo yemfucuza engaphezulu: izendlalelo, amabhamuza, imifantu ye-extrusion, ikhasi lewolintshi, izigaba zethishu, amabala amnyama, ulayini wokushisela we-longitudinal, umugqa wokushisela ophambanayo, ukuklwebheka, ukucindezela kwensimbi, njll.

Imikhiqizo yemfucuza yobukhulu beJomethrikhi: igagasi, ukusonteka, ukugoba, imvume yendiza, usayizi ongabekezeleleki, njll.

Izinga lemikhiqizo eqediwe ukuhlukaniswa kwezinga lokulandelana kwabasebenzi lemikhiqizo eqediwe kanye nesivuno esiphelele.

Inqubo eqediwe aluminium isilinganiso ngokuvamile ibhekisela inqubo main, ngokuvamile esekelwe workshop njengoba iyunithi calculation.Casting inqubo (casting workshop), inqubo extrusion (inqubo extrusion), inqubo oxidation Umbala (i-oxidation workshop), inqubo powder sishaye (spraying workshop ).Kuchazwa njengesilinganiso sokuphuma okufanelekile kweshabhu nokufaka izinto ezingavuthiwe (noma imikhiqizo eseqediwe kancane) endaweni yokusebenzela.

Izinga lemikhiqizo eqediwe lihlobene nekhwalithi yemishini, ikhwalithi ye-ingot, ukwakheka komkhiqizo, imvamisa yokushintshwa kwezinhlobonhlobo kanye nokucaciswa, izinga eliphezulu lobuchwepheshe, izinga lokuphathwa kwebhizinisi kanye nekhwalithi yabaqhubi nezinye izici.

Isihluthulelo sokuthuthukisa isivuno samaphrofayili e-aluminium alloy ukunciphisa nokuqeda udoti.Imfucuza yeJiyomethri ayinakugwenywa, kodwa ingancishiswa.Imfucuza yobuchwepheshe iyisici somuntu, esingaqedwa esimweni ngasinye noma sincishiswe. .Ngakho-ke, ukulawula okusebenzayo kanye nokwenza ngcono isivuno semikhiqizo ekhishwe ngaphandle kungamukelwa.

Ukunciphisa imfucuza yejometri kuyisidingo esibalulekile sokuthuthukisa isivuno semikhiqizo eqediwe

Izinyathelo zokunciphisa udoti wejometri

Ukukhetha okulungile kobude be-ingot yisilinganiso esiyinhloko sokunciphisa udoti wenqubo.Ubude be-ingot abubalwa ngemva kokukhishwa, kodwa bubalwa ngemva kokukhishwa.

Manje amabhizinisi amaningi asebenzisa isithando somlilo esishisayo se-shear aluminium ende, uma kuqhathaniswa nesithando sokushisa induku emfushane, anciphisa ukulahleka kwama-chips e-aluminium, ngenxa yokushintsha kokuqina kodonga lwesikhunta, ukulawulwa kobude bokuphonsa kuvumelana nezimo futhi kunembile, kuthuthukisa kakhulu. isivuno.Kodwa amabhizinisi amaningi ekusebenziseni isithando somlilo esishisayo senduku ende, azinaki izibalo zobude bokudubula, futhi anikeze ngokuqondile umsebenzi ku-opharetha ukuze alawule.Futhi u-opharetha ngokuvamile usekelwe kokuhlangenwe nakho ngaphansi kwebha yokuqala, qaphela ubude bezinto ezibonakalayo, uma umehluko mkhulu, qhubeka ulungisa, ngokuvamile udinga imigoqo emi-3 ukuze uthole ubude obunembile.Kule nqubo, kukhishwe imfucuza eminingi, okunciphisa kokubili ukusebenza kahle kokukhiqiza kanye nesivuno.

Indlela efanele iwukuthi ubude be-ingot bubalwa ngumnyango wokulawula inqubo ngesikhathi sokukhiqizwa kokuqala kwesikhunta.Lapho isikhunta sikhiqizwa emshinini izikhathi eziningi, ubude benduku erekhodiwe ekhadini lesikhunta bukhuphuka kancane cishe ngo-5-10mm, futhi ubude bezinto ezibonakalayo bubhekwa lapho kukhiqizwa impahla.Ukulungiswa kahle uma kukhona Umehluko.Ngakho-ke induku yesibili inembe kakhulu.Ngokwedatha ethile, isivuno semikhiqizo eqediwe singanyuswa ngamaphesenti ama-4 ngokusebenzisa izishefa ezinde ezishisayo, futhi kungenzeka ngokuphelele ukwandisa isivuno ngamaphesenti angu-2 kuya kwangu-3 ngokwangempela. ukukhiqiza.

Ngaphezu kwalokho, inombolo yobude obunqunyiwe noma ubude bomkhiqizo, ukuze kuqinisekiswe umsebenzi we-extrusion obushelelezi ngaphansi kwesisekelo se-extrusion.Lapho ubude bombhede obandayo bude ngokwanele, khulisa ubude bosayizi ohleliwe noma ubude bemikhiqizo. ngangokunokwenzeka, okungukuthi, ingot ende ingase ikhethwe.Kubuye kube indlela ephumelelayo yokunciphisa iphesenti lemfucuza yejometri nokwandisa isivuno semikhiqizo eqediwe.

Izinyathelo zokuthuthukisa izinga lemikhiqizo eqediwe kusukela ezingeni lobuchwepheshe

Kuyisilinganiso esibalulekile sobuchwepheshe ukuthuthukisa izinga lemikhiqizo eqediwe ukuze kuthuthukiswe izinga lokuklanywa kwesikhunta kanye nokukhiqizwa kanye nokunciphisa i-Times yokuhlolwa kwesikhunta.Ngokuvamile hhayi lesi sikhunta sokuhlola esibiza ama-ingots angu-1-3, ukuze isivuno sehle ngo-0.5-1 %, ngenxa yokuklanywa kwesikhunta, izinga eliphansi lokukhiqiza, eminye imikhiqizo yokulungisa isikhunta, isikhunta izikhathi ezingu-3-4 noma izikhathi ezingaphezu kokukhiqiza imikhiqizo ephelile, inciphisa ngokungabonakali isivuno sika-2-5%, okungeke kubangele umnotho kuphela. ukulahlekelwa, kodwa futhi ngenxa yesikhunta sokuhlola esiphindaphindiwe, kuzonweba umjikelezo wokukhiqiza.

Umqondo wanamuhla wokuhlola isikhunta u-zero, okungukuthi, ngemva kokuba isikhunta senziwe, asikho isidingo sokuhlola isikhunta, ungakwazi ngokuqondile emshinini ukukhiqiza imikhiqizo efanelekayo.Usebenzisa isofthiwe yokuklama ukulingisa, ukuhlaziywa kwezinto ezinomkhawulo, ukuklama kungaqedwa ikhompuyutha.Ingabuye ihlolwe nge-computer simulation.Ukucutshungulwa komgodi wesikhunta kuqediwe esikhungweni somshini othomathikhi, ukucutshungulwa kwesikhunta sonke kunembile kakhulu, ngakho ikhwalithi yesikhunta iphezulu kakhulu.Emshini wokuphasa ngaphezu kokudlula 90%.Inganyusa isivuno semikhiqizo eqediwe ngo-2-6%.

Khulisa ngokufanelekile i-extrusion coefficient ye-aluminium ukuze uthuthukise isivuno

Imboni ngayinye ye-aluminium inochungechunge lwemishini, imboni ngayinye ngokwesilinganiso sokukhishwa komkhiqizo, ubude bombhede obandayo, ingxenye yangaphandle yomkhiqizo, ubude be-extrusion cylinder diameter, ukunquma umkhiqizo emshinini ohambisanayo. ukukhiqiza.Ukuzijwayeza kufakazele ukuthi ukucaciswa okufanayo kwemikhiqizo, kufakwa ekukhiqizeni umshini we-tonnage we-extrusion ehlukene, ngenxa ye-coefficient ye-extrusion ehlukene, ukwakheka kokusebenza komkhiqizo nokusebenza kahle kokukhiqiza kunomthelela omkhulu, isivuno sawo sizophinde sikhiqize umehluko.Lapho i i-extrusion machine tonnage inkulu, i-extrusion coefficient inkulu, izinga lomkhiqizo oqediwe liphakeme, futhi izindleko ze-extrusion ziseduze.

Ukuthuthukisa ikhwalithi ye-ingot kuyisisekelo sokuthuthukisa isivuno

Ama-ingots ayizinto zokusetshenziswa zokukhiqizwa kwe-extrusion.Ama-ingots anesakhiwo esifanayo, okusanhlamvu okuhle, akukho-slag, ama-pores, ukuhlukaniswa, ukuqhekeka nezinye iziphambeko, ezingakwazi ukunciphisa ukucindezela kwe-extrusion kuphela, ukuthuthukisa isivinini se-extrusion, nokuthuthukisa ikhwalithi yangaphakathi yemikhiqizo.Futhi inganciphisa ama-bubbles ebusweni bomkhiqizo, ama-pores, imihuzuko, ukuqhekeka, i-pitting kanye nezinye iziphambeko.Ukufakwa kwe-slag encane kungakhishwa ngokusebenzisa i-slit yebhande elisebenzayo lesikhunta, kodwa kuzodala amamaki e-pear ebusweni bephrofayili, okuholela ebude obuthile bemfucumfucu.Ukufakwa kwe-slag enkulu kuzokwenza ubhajwe esikhaleni sebhande elisebenzayo futhi awukwazi ukuqedwa, okuzokwenza ipulaki yesikhunta noma imikhiqizo iqhekeke bese ibuyisela isikhunta, okuzothinta kakhulu isivuno.Sebenzisa amaphedi ahambisanayo lapho welula futhi uqondisa ukuze unciphise ubude bokusika kwekhanda nomsila. impahla.

Iphrofayili ekululekeni kokuqondisa, amabhizinisi amaningi awaklami umcamelo ohambisanayo, ikakhulukazi iphrofayili enkulu elengayo kanye nephrofayili engenalutho.Ngenxa yalokho, ukuguqulwa kwekhanda nomsila wephrofayili kukhulu kakhulu, futhi ingxenye yokuguqulwa kufanele inqunywe lapho. ukubona umkhiqizo oqediwe.Lokhu kubangele ukwehla kwezinga lemikhiqizo eqediwe.

Umcamelo ungenziwa ngokhuni oluqinile noma amabhulokhi e-aluminium.Idizayini inciphisa usayizi womcamelo futhi ikhulise ukuguquguquka kwayo.Ngodonga olude nengxenye evaliwe yephrofayili, ukuqondisa endaweni evalekile ibe yiphedi kodwa futhi ibeke ifreyimu yokusekela engxenyeni yodonga.Ngakho, ukuwohloka isiqondiso sobude sincishisiwe.Ukulungiswa kufanele kuklanywe, kuphathwe futhi kuqondiswe abasebenzi abakhethekile.

Ngesikhathi esifanayo, ukuze kuvinjwe into yokuthi abasebenzi abazimisele ukusebenzisa umcamelo ngenxa yenkinga, kufanele sisungule indlela yomvuzo kanye nesijeziso sokuthi izinga lomkhiqizo oqediwe lixhunywe nomholo.

Qinisa ukuphathwa kwe-extrusion die kanye nerekhodi loqobo lokukhiqiza lephrofayili ye-aluminium.

Ikhadi lesikhunta kanye nerekhodi lokuqala lokukhiqiza kubaluleke kakhulu.Ikhadi lesikhunta kufanele likwazi ukukhombisa ngempela isimo se-nitriding sesikhunta, isimo sokugcinwa kanye nesimo sezinto ezibonakalayo.Irekhodi langempela kufanele likwazi ukukhombisa ngokweqiniso ukuthi isisindo sokusekela, ubude bokuphonsa kanye nenani linikeza isisekelo esithembekile sokukhiqiza okulandelayo.

Manje amabhizinisi amaningi aphinde aqaphela ukuphathwa kwedatha yekhompuyutha, kodwa kusenendlela ende okufanele ihanjwe ekusetshenzisweni kwangempela.

Yehlisa udoti wejiyomethri ngokusebenzisa i-afterextrusion engacindezeli

Iphedi egxilile igxilile ku-extrusion rod ngaphandle kwe-extrusion eyinsalela, futhi kokubili kushintshwa kuze kufike ezingeni elithile.Lapho isilinda sokukhipha singahlehli, iphedi yokucindezela kulula ukuyihlukanisa nengot.Ingot elandelayo ibe isiphushwa ngokuqondile. kukhatriji ye-extrusion.Inwetshwe nensalela yengothi yangaphambilini, ngaleyo ndlela kugwenywe isidingo sokugunda ingothi ngayinye kanye.Ngokuvumelana nezidingo zekhwalithi kanye nenani le-oda ukuze kutholwe inani lomshini wokugunda we-shear. Ngokuvamile izingcezu ezingama-40-50 zisikwa endaweni eyodwa. isikhathi.

Lungiselela inqubo ye-extrusion yamaphrofayili e-aluminium ukuze unciphise imfucuza yobuchwepheshe

Kunezici eziningi ezithinta inqubo ye-extrusion yemfucuza yezobuchwepheshe, ehlanganisa yonke inqubo yokukhiqiza i-extrusion.Ikakhulukazi ihlanganisa: ikhwalithi ye-ingot, izinga lokushisa lenqubo, isivinini se-extrusion, amathuluzi we-extrusion, ifa, ukulayishwa kokudlulisa nokukhipha, ukwelashwa kokuguga, njll.Ngaphezu kwalokho ukuthuthukiswa kobuchwepheshe obuphambili, besayensi yokukhiqiza, kodwa futhi nokuqaliswa okuqinile kwezinqubo zokusebenza, ukuthuthukisa amakhono abasebenzi kanye nomuzwa wokuzibophezela.

Ngangokunokwenzeka ukunciphisa ukukhiqizwa okuhlukahlukene kokushintsha ngakunye, kungcono ukuhlela izinhlobo ezingu-3-5 kuphela nge-shift ngayinye, ukuthuthukisa ukukhiqizwa kweqoqo elilodwa lokubunjwa.Izinhlobo eziningi emshinini, i-aluminium isikhunta izoba ngaphezulu. ukususwa, isivuno siphansi.

Umphumela wesikhunta esivunweni ikakhulukazi ezicini ezimbili: ukuhlolwa kwesikhunta esisha kanye nokusetshenziswa kwesikhunta sokukhiqiza.

Lapho isikhunta sizanywa izikhathi eziningi, isikhunta siyasuswa, futhi isivuno siyancipha.

Ukukhiqizwa kwesikhunta kufanele kugcinwe ngokucophelela, i-nitriding enengqondo, ukugcinwa ngesikhathi esifanele.Qinisekisa isikhathi ngasinye emshinini isilinganiso esifanelekayo siphezulu.Ukubumba okuhle nokuqina okuphezulu.Uma ukushintshwa ngakunye ngenxa yokugcinwa kwesikhunta kungafaneleki, okuholela ezinhlobonhlobo ezingu-3-4 ekuhlulekeni kokukhiqizwa komshini , izinga lemikhiqizo eqediwe lizokwehliswa okungenani ngephuzu elilodwa.

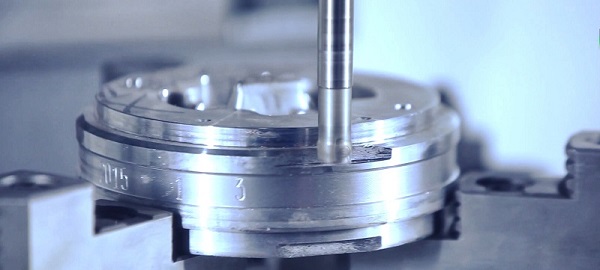

Amathuluzi e-Aluminium extrusion ahlanganisa: i-cylinder extrusion, i-extrusion rod, i-extrusion pad, i-die pad, njll.Ikakhulukazi ukuqinisekisa ukuthi i-cylinder extrusion, induku, isikhunta ezintathu ze-concentric.Okwesibili, ukugcinwa okunengqondo kwe-cylinder extrusion, ukushisa okulungile, ukuqinisekisa ukuthi ukuphela indawo yesilinda ibushelelezi.Susa zonke izinhlobo ze-extrusion cylinder futhi ufe ngento embi.Hlanza i-aluminium esele odongeni lwangaphakathi lwesilinda sokukhipha njalo, hlola ukuthi udonga olungaphakathi lwembobo yonakele yini, sebenzisa i-die pad ngendlela efanele, futhi ngcono amandla okusekela of the die.

Ukushisa kwe-Extrusion, isivinini se-extrusion kanye nokupholisa okuthathu, esakhiweni somkhiqizo, izakhiwo zemishini, izinga eliphezulu linomthelela omkhulu, lizophinde lithinte isivuno.Ngaphezu kwalokho, lezi ezintathu zizothinta ubude bomkhiqizo, izinga lokushisa lenduku yokuphonsa liphezulu, isivinini se-extrusion siyashesha, izinga lokupholisa liphansi, lizokwenza ubude bomkhiqizo ngemva kokukhuphuka kwe-extrusion, izinga lokukhula lingaba ngu-0.5% - 1%, liphinde lithinte ukuminyana komugqa wephrofayili, ukuze inqubo ezinzile ingakwazi. ngcono isivuno.

Thuthukisa inqubo ye-extrusion elandelayo ukuze ugweme imfucuza yobuchwepheshe.Ukwelula inqubo yokuthutha elandelayo, ikakhulukazi qaphela iphrofayili yokuklwebheka.

I-extrusion eyodwa ye-porous ingenza ngcono isivuno semikhiqizo eqediwe.

Kweminye imikhiqizo elungele i-multi-air extrusion, ngangokunokwenzeka usebenzisa i-porous extrusion, ayikwazi nje ukunciphisa i-extrusion coefficient, ukunciphisa nokucindezela, kodwa futhi ingathuthukisa isivuno.Ngaphansi kwesimo sokuthi imfucuza yezobuchwepheshe ingu-zero, isivuno i-double hole extrusion inganyuswa ngo-3% ~ 4% kunaleyo ye-extrusion yembobo eyodwa.

Isivinini se-Extrusion siyipharamitha yenqubo ebalulekile enqubweni ye-extrusion, ehlobene nekhwalithi yemikhiqizo kanye nokusebenza kahle kokukhiqiza.Ijubane le-Extrusion alifani nokwazi kahle izinga lokushisa lenqubo, uhlobo lwe-alloy inqubo yokwelapha ukushisa lungakhetha ngokuyisisekelo izinga lokushisa, futhi ijubane le-extrusion liyipharamitha yenqubo enamandla kakhulu.Amaphrofayili e-alloy ahlukene anezigaba ezihlukene anezivinini ezihlukene ze-extrusion.Umkhiqizo ofanayo uthintwa ukushintsha kwezinga lokushisa kunqubo ye-extrusion, futhi izivinini ze-extrusion zihlukile ngaphambi nangemva kwe-extrusion.Ukuze ulawule kahle isivinini sokukhipha, kufanele kube:

Ngekhono nangokuguquguqukayo bamba ububanzi besivinini sokukhipha ama-alloys ahlukahlukene, izigaba ezihlukahlukene (okuhlanganisa ukushuba kodonga), futhi unake umthelela wejubane lokukhipha kumaphrofayela e-aluminium, njengekhwalithi yendawo ephezulu, idigri yokubumba, njll.

Ujwayelene nekhono lemishini ye-extrusion ukuze ulawule isivinini se-extrusion.Amanye ama-extruder ane-extrusion control njalo kanye nokulawula kwe-PLC, amanye anokulawula kwe-PLC kuphela, kanti amanye awanakho lutho.Lapho ijubane elinikeziwe lokukhipha, amanye ama-extruder angaqala ukucindezela isivinini sokukhipha ngokunciphisa kancane kancane kwe-billet ku-cylinder extrusion, ingcindezi ye-extrusion iyancishiswa, isivinini sokuphuma komkhiqizo sizoshesha futhi sisheshe, ngezinye izikhathi senze umkhiqizo ngemva kokuqhekeka.Ngakho-ke, kuyadingeka ukulungisa isivinini se-extrusion.Kuphela kuphela ukuqonda isimo semishini isivinini se-extrusion singalungiswa kahle futhi silawulwe.

Qonda umthelela wesikhunta esihlukene ngesivinini se-extrusion.Ngokuvamile, ijubane lokukhipha i-flat die (iphrofayili eqinile) liphakeme kunelo lokuhlukaniswa kwe-die (iphrofayili engenalutho).Kodwa uhlobo olufanayo lwesikhunta, ukuma kwesigaba esifanayo somkhiqizo, ngenxa yokuklama kanye nezinga lokukhiqiza lihlukile, isivinini se-extrusion sihlukile.Ikakhulukazi, isigaba sinomehluko wokuqina odongeni, noma iphrofayili engenalutho ene-open, enobudlelwane obukhulu nesikhunta.Ijubane elithile kuphela le-extrusion eliklanywe isikhunta lihamba phambili.Ijubane lishesha kakhulu noma lihamba kancane, futhi kulula ukukhiqiza ukusonteka nokuvula nokuvala.

Yehlisa ukukhiqizwa kukadoti ngokuqinisa ukuhlolwa kokuqala kanye nokuhlolwa kwenqubo

Ubukhulu bangaphandle bemikhiqizo ye-aluminium yemfucuza, njengokuqina kodonga ngenxa yokubekezelelwa, ukusonteka, imvume yendiza, ukuvulwa noma ukuvala, njll., kuncike kakhulu entweni yokuqala ngemva kokuhlolwa kwesikhunta ngesandla somsingathi ekuhlolweni kokukhipha kanye nomhloli wekhwalithi. ekuhlolweni okuqinile ukuvimbela ukukhiqizwa kwemikhiqizo enjalo yemfucuza.Ukubekezelelana kodonga olujwayelekile kufanele kulawulwe ekubekezeleleni okungalungile, ngoba ngokukhiqizwa okuqhubekayo kwemikhiqizo, ukushuba kodonga lwemikhiqizo kuzokhula kancane kancane ngenxa yokuguga kancane kancane. wesikhunta.Kumaphrofayili amakhulu odonga, lapho udweba futhi uqondisa ukuze uhlole ngokucophelela umdwebo, lawula inani elifanele lokwelula.

Imfucuza engaphezulu efana nokuklwebheka, ikhasi lewolintshi, izicubu, amabala amnyama, amabhamuza, ngokuvamile akuveli yonke imikhiqizo yempande.Kuyadingeka ukuhlolana ngomqhubi womsingathi, umhloli wekhwalithi kanye nenqubo yokusaha yokwelula umkhiqizo ophelile, futhi aqondise ngokuhlanganyela ukukhishwa kwemfucuza endaweni.

Uma umhloli wekhwalithi engatholi imihuzuko etafuleni lokukhipha, futhi ethola imihuzuko emikhiqizweni eqediwe lapho ebona, kuyadingeka ukuthi ahlole inqubo yokuguqulwa kombhede obandayo ukuze abone ukuthi ezinye izingxenye zebhande lokuthutha, i-digger nokunye. ziqinile futhi zivelele, okubangela imihuzuko.

Ukuphathwa kwekhwalithi wukuphatha kwabasebenzi bonke kanye nohlelo lonke.Inqubo ngayinye kufanele ibe nekhwalithi enhle, ukuze ukuzihlola, ukuhlola okuhlangene nokuhlola okukhethekile kungahlanganiswa, ukuze kuqedwe ngokuphumelelayo imfucuza yezobuchwepheshe ku-bud.Ukulawula okwenziwayo nokuthuthukisa isivuno.

Ngokusebenzisa lezi zinyathelo ezingenhla kunganciphisa imfucuza yejiyomethri, kungabonakala ukuthi ukuncishiswa kwemfucuza yejiyomethri kuyizinyathelo ezibalulekile zokuphatha ezobuchwepheshe zamabhizinisi, ezinokubaluleka okukhulu kwezinzuzo eziphezulu zezomnotho.

Ukuthuthukisa isivuno se-aluminium extrusion billet ukuqedela kanye nenqubo yokusebenza ngokucophelela yokukhiqizwa kwe-extrusion, hhayi izici zobuchwepheshe kuphela okufanele zibe khona, kodwa futhi izici zokuphatha kufanele zibe endaweni.Kusenendawo enkulu yephrofayela ye-aluminium yaseChina. amabhizinisi ukuthuthukisa isivuno, isivuno kuyoba inqubo eqhubekayo, ukuthuthukisa isivuno kanye nokwenza ngcono ikhwalithi yomkhiqizo, okukhiphayo kuxhumene eduze.Iwubuchwepheshe bebhizinisi kanye nezinga lokuphatha le-embodiment ephelele.

Thuthukisa umkhiqizo we-aluminium enombala ene-oxidized

Isivuno se-oxidation siyisivuno somkhiqizo owodwa, okungukuthi, isivuno somkhiqizo owodwa ngaphandle kokusebenza kabusha.Ngokomkhuba wokukhiqiza, izindleko zamaphrofayili asetshenzwe kabusha ziphindwe izikhathi ezingu-3 kunamaphrofayili angasebenzanga kabusha, futhi ikhwalithi yangaphezulu yamaphrofayili ayikwazi ukuqinisekiswa.Yiqiniso, ikhwalithi yemikhiqizo ene-oxidized iqala kusukela ku-workshop yokukhipha.Ngenxa yemikhawulo yesikhala, okulandelayo yinkulumo emfushane mayelana nemininingwane ethile okufanele inakwe enqubweni yokukhiqiza i-oxidation.

Isikulufu esiphakathi kwenduku yokulenga kanye ne-conductive beam kufanele sivamise ukuqiniswa.Ngaphambi kokubopha impahla, kufanele siqale sihlole ukuthi induku yokulenga iqinile yini.Uma ikhululekile kancane, kufanele iqiniswe ngesikhathi.Enye ukugqwala, induku yokulenga izoba yincane, idinga ukushintshwa ngesikhathi, ngoba indawo yayo yokuhambisa incane, kulula ukubangela ukushisa, ngesikhathi esifanayo ukubopha, ukuvimbela iphrofayili ewela ku-slot okubangelwa isigxobo, ukulimala kwesifunda esifushane kumthombo wamandla.

Ngasikhathi sinye, ukuwela kuphrofayili yethangi kufanele kuhlanzwe ngesikhathi, njengethangi lokuwasha le-alkali libe yiphrofayili, lizogqwala maduze, ucwaningo lwafakazela ukuthi ukusetshenziswa kwe-alkali kulingana nokuwashwa kwe-alkali kuka-50-100. impande yephrofayili yokusetshenziswa kwe-alkali.Ukuwela ethangini lombala noma ithangi lokuvala, ngenxa yokugqwala, ithangi lizoqongelela inani elikhulu lama-ion e-aluminium, okuthinta impilo yesevisi yoketshezi lwethangi.

Izinto ezibophayo ngocingo lwe-aluminium ezinezinhlobo ezimbili zokucaciswa zilungile, i-aniseed ukukhetha ucingo lwama-aluminium amaholo, impahla ephakathi nendawo encane isetshenziswa ocingweni lwe-aluminium emihle, ingasetshenziswa 2mm no-3mm, noma 2.2mm no-3.2mm izinhlobo ezimbili zokucaciswa, i-aluminium. ukuqina kwe-wire annealing kuthatha 1/2~3/4 kuhle.Okwamanje, amabhizinisi amaningi aguqulelwe ku-jig.

Ngaphambi kokulenga ethangini le-oxidation ukuze uqinise iphrofayili ngayinye; I-rework material ngaphambi kwe-oxidation yezinto ezibonakalayo, ukusebenzisa izidladla ukushaya ukuphela kwephrofayili ukuze kuguqulwe ngaphambi kwempahla, ukuze othintana naye ngaphandle kwefilimu, ukuqinisekisa ukuqhutshwa okuhle. .

Thayipha impahla elenga ithangi le-oxidation kanye nesihlalo sokushayela ithangi lombala kufanele sinake kwesokudla, kungenjalo sithambekele kumehluko webala le-Yin ne-Yang.

Ngemuva kokuthi ukuphela kwamandla e-oxidation kumisiwe ngesikhathi, ukuhlala ethangini le-oxidation imizuzu embalwa kuzothinta imbobo yokuvala, futhi kuzokwenza isivinini sombala;Ngemva kwe-oxidation, iyaphakanyiswa futhi itshekiswe emoyeni isikhathi eside kakhulu.Umkhawulo owodwa wesisombululo sokunciphisa i-asidi uba mnyama ngenxa yokwanda kwembotshana yefilimu ye-oxide, futhi umehluko wombala kuzo zombili iziphetho kulula ukuvela.

Inani le-pH lamathangi amane okugeza amanzi ngaphambi nangemuva kwethangi lokufaka imibala kufanele ligcinwe lizinzile.Inani le-pH lamathangi amane okugeza amanzi ajwayelekile lilawulwa kanje:

Inani le-pH lokugeza kwamanzi okuqala ngemva kwe-oxidation: 0.8~1.5

Inani le-pH lokugeza kwamanzi kwesibili ngemva kokufakwa kwe-oxidation: 2.5~3.5

Inani le-pH lokugeza kwamanzi okuqala ngemva kokufakwa umbala: 1.5~2.5

Inani le-pH yethangi lokuwasha lesibili ngemva kokufakwa umbala: 3.5~5.0

Ngaphansi kwezimo ezijwayelekile, inani elithile lamanzi aphuphumayo liyavuleka ngesikhathi sokukhiqiza, futhi i-valve yokungena ivaliwe ngesikhathi lapho ukukhiqizwa kumisiwe.Akufanele ikhiphe amanzi noma ingeze amanzi ethangini lonke.Uma amanzi ehlala ethangini lokuqala lokugeza ngemuva kwe-oxidation imizuzu embalwa, isivinini sombala sizosheshiswa, futhi uma amanzi ehlala ethangini lokuwasha lesibili, umbala uzokwehla.

Ukuze kukhiqizwe okokusebenza kwensimbi okulingisa okunombala okhanyayo, indlela yombala ivame ukwamukelwa kuqala, bese ibuyela epuleti lombala elijwayelekile.Ngenxa yomehluko wombala webanga lokulawula isikhathi sensimbi yokulingisa lincane kakhulu (amasekhondi angu-2~3 kuphela) , futhi ukusebenzisa umthetho wokufiphala kungaba namasekhondi angu-10~15 wesikhathi sokulawula umbala, futhi ukufiphala okuhlanganisiwe nakho kulungele umbala ofanayo wangemuva, ngokufiphala kwensimbi yokulingisa nemibala ehambisanayo umbala uvame ukuphenduka ube luhlaza, futhi umbala wesikhathi esisodwa uvame abebomvu.

Thayipha impahla elenga ethangini lombala kanye nethangi lokuqala lokuwasha ngemuva kokufakwa umbala ngemuva kokulenga ungayeki isikhathi esingenalutho side kakhulu, ngaphandle kwalokho indawo yephrofayili izovela iribhoni, umbala ongalingani kanye nokuphela kokukhishwa kwento emhlophe, kufanele kube kancane embala ukugeza okulandelayo ngesikhathi, umbala onembile kufanele ube sewashi lesibili ngemva.Ngokuvamile, ngokulingisa impahla yensimbi, njengombala wesifanekiso sokuqhathanisa obomvu, kukhombisa ukuthi isikhathi sokufaka imibala asanele ukuhambisana nombala;Uma umbala uphuzi. , ifakwe umbala, ngokusho kokujula kombala, ungakhetha ukuhlehla ethangini lombala noma ku-tank yokuqala yokuwasha ngemva kombala.

Indlela yokwengeza yezidakamizwa ethangini lombala: i-stannous sulfate ne-nickel sulfate kufanele ichithwe ethangini, futhi isithasiselo sombala kufanele sihlakazwe emanzini ahlanzekile (amanzi ahlanzekile ayancibilika).Kumele kuqashelwe ukuthi isithasiselo esiqinile singathululwa ngemva kokuqedwa ngokuphelele, futhi i-sulfuric acid egxilile ingathululelwa ngqo ethangini lombala.

Izinga lokushisa, isikhathi kanye nekhwalithi yamanzi okugeza amanzi ashisayo ngaphambi kwe-electrophoresis kumele kuqinisekiswe.Uma i-SO42- esele emgodini wefilimu ye-oxide ingagezwa, ukuphuzi nokufiphala kwefilimu kapende kungenzeka kwenzeke ngemuva kwe-electrophoresis nokubhaka.Ngaphansi kwezimo ezijwayelekile, izinga lokushisa lamanzi ashisayo lilawulwa ku-60 ~ 70℃, kanye nokugeza kwamanzi ashisayo. isikhathi 5 ~ 10 imizuzu.

Isikhathi sokuthumela: Mar-26-2021